Bonna Complete Technical Solution

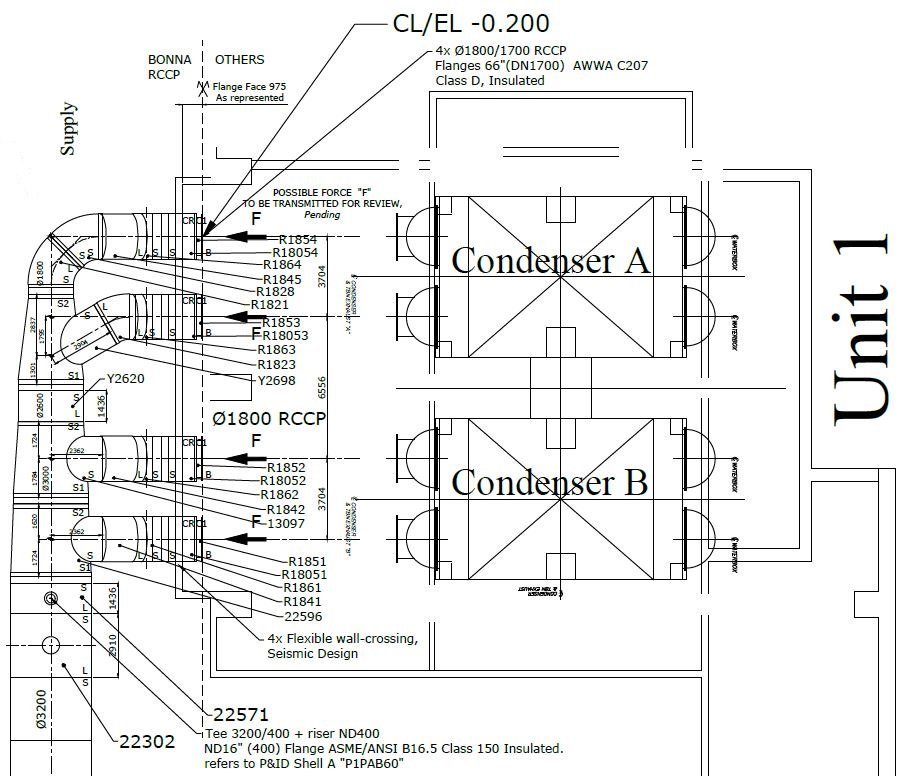

Bonna can provide customer with a complete technical solution for onshore project such as: cooling water system and FGD system, desalination pipeline of power plant, cooling water system for industrial plant, pipeline for water supply, penstock and waterway for hydropower plant.

Power Plant

Desalination Plant

Refinery

Infrastructure

Water Transmission

Fertilizer Plant

Petrochemical Plant

Six Key Advantages of Bonna RCCP for Onshore Project

1. Large Diameter

Manufactured up to 4,000 mm in diameter for high flow capacity

2. Loads Capacity

Rugged & support heavy equipment loads during construction

3. Durability

Durable and reliable, ensuring a lifetime of dependable service

4. Simplified Construction

Easy to connect and required less compacted backfill

5. Low head loss

Smooth, with low head loss characteristics for low-cost performance

6. Custom-made solution

Custom-designed for the project needs and configuration

1. Large Diameter

- Bonna Pipe RCCP is manufactured up to 4,000 mm in diameter

- Water pipelines and industrial plants use and circulate large quantities of water that needs large-diameter pipe

- Large diameters deliver water with desirable velocities, lower friction losses, and therefore lower pumping costs

2. Loads Capacity

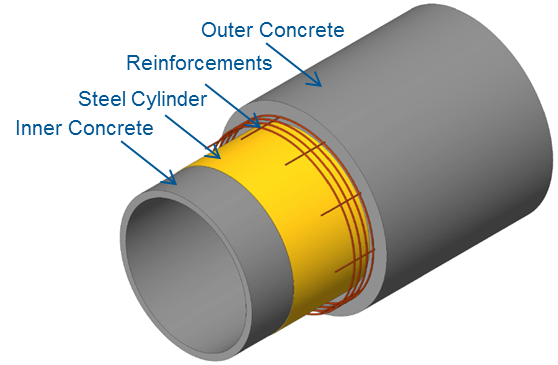

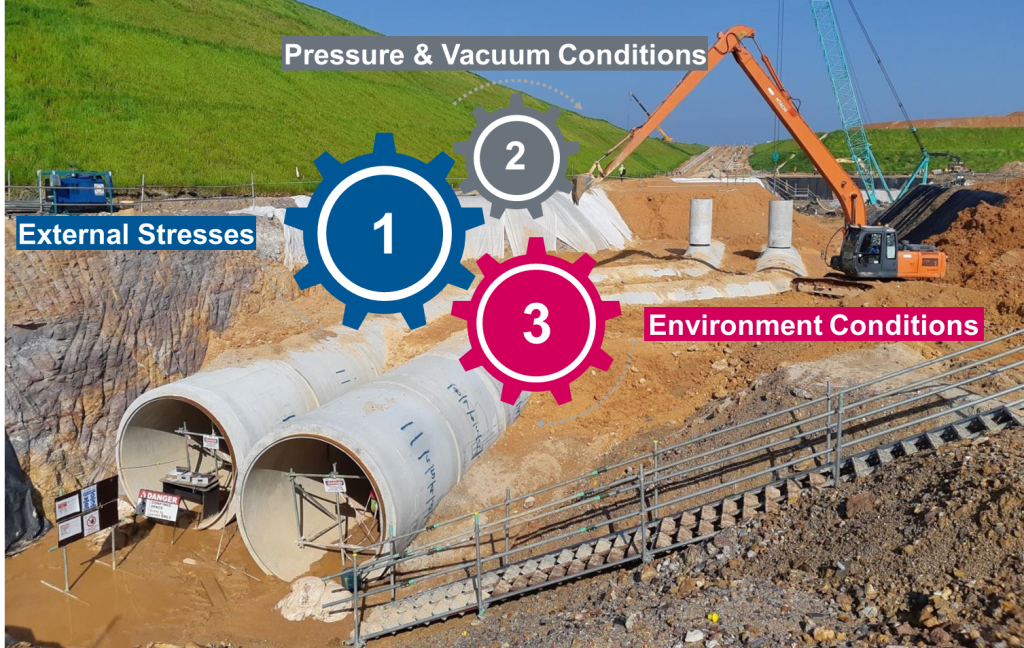

- Bonna Pipe RCCP is designed to resist the combined loading of internal pressure and external loads

- Its high external load capacity derives from the high compressive strength of concrete

- Therefore, since the buried water piping is installed before surface construction can progress, Bonna Pipe RCCP’s ability to resist construction equipment loads is essential

3. Durability

- The RCCP pipeline withstands full vacuum conditions

- The protection of steel by concrete is permanent, therefore no need for maintenance

- Bonna pipe concrete inner wall does not require any specific protection against abrasion thanks to its high strength & compactness

- Concrete high thermal inertia makes the pipeline less sensitive to the weather conditions

4. Simplified Construction

- Easy joints connection whether it is welded Thrust-Restrained or flexible joints

- Bonna Pipe RCCP only requires compacting backfill up to the pipe springline

- Bonna RCCP pipeline does not need thrust block at bends

- Easy to connect to civil structure with wall crossings

- All kind of Special Fittings are available for Bonna RCCP

5. Low Head Loss

- Roughness Coefficient “k”=0.0001m corresponds to the internal lining of the Bonna pipelines RCCP

- The manufacturing and installation processes for Bonna Pipe RCCP result in pipelines with smooth surfaces across the joints between adjoining pipe units

- The concrete or mortar lining does not deteriorate with age when flowing full

6. Total Custom-made Solution

Before execution of the contract, Bonna Pressure Pipes’ design and engineering office helps customers to optimize their system and works with you for all the technical aspects.

During the performance of the contract, the design and engineering office works out all the technical documents required for the project. In particular:

– The bills of materials and piping arrangement drawings for the pipes and special fittings for manufacturing and for laying

– Detailed drawings of the equipment and/or accessories supplied

– Calculations notes

– The erection manual and instructions on the protection systems to apply on site

Looking for solutions for your next project?

DISCOVER OUR REFERENCES

Achievements

Discover our main achievements in pressure pipe activity since 1993 when we set up PT.

Bonna Indonesia for Black Point project in Hong Kong.