Bonna Complete Technical Solution

Bonna can provide customer with a complete technical solution for offshore project such as: cooling water system for power plant and industrial plant, cooling water system for refinery, intake pipeline for desalination plant and discharge pipeline for water treatment plant.

Power Plant

Desalination Plant

Refinery

Infrastructure

Water Transmission

Fertilizer Plant

Petrochemical Plant

5 Key Advantages of Bonna RCCP for Offshore Project

1. Large Diameter

Manufactured up to 4,000 mm in diameter for high flow capacity

2. Durability

Durable and reliable, ensuring a lifetime of dependable service

3. Simplified Construction

Easy to connect underwater and required less civil works

4. Low head loss

Smooth, with low head loss characteristics for low-cost performance

5. Custom-made solution

Custom-designed for the project needs and configuration

1. Large Diameter

- Bonna Pipe RCCP is manufactured up to 4,000 mm in diameter

- Industrial plants use and circulate large quantities of water that needs large-diameter pipe

- Large diameters deliver cooling water with desirable velocities, lower friction losses, and therefore lower pumping costs

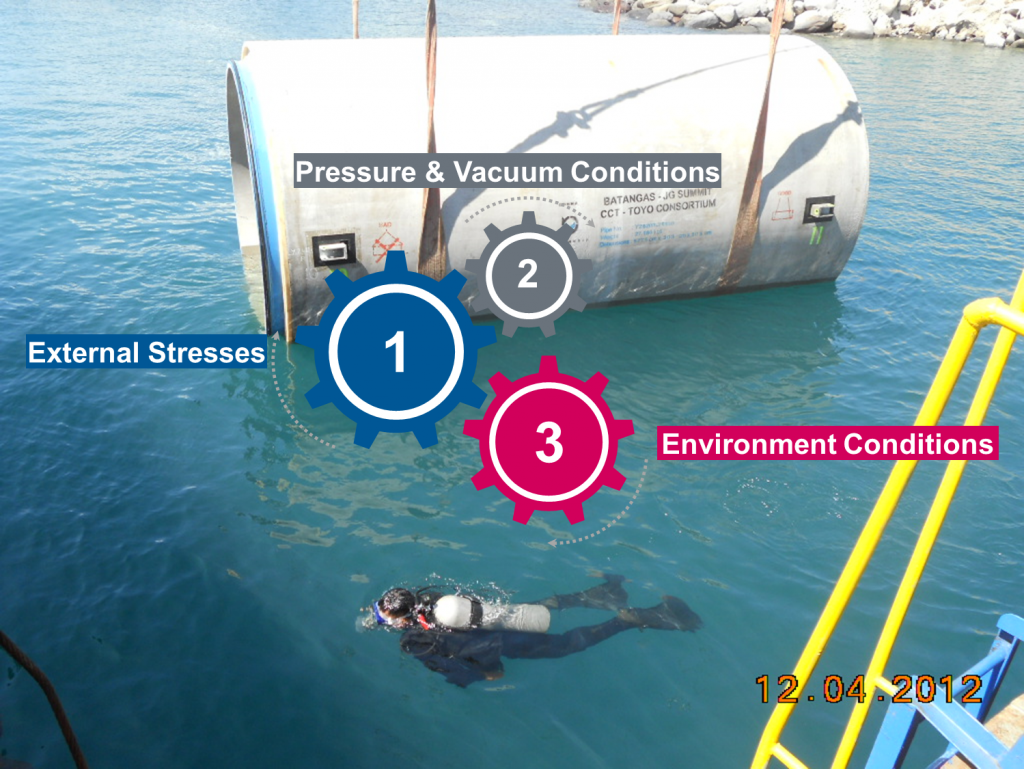

2. Durability

- The RCCP pipeline withstands full vacuum conditions

- The protection of steel by concrete is permanent, therefore no need for maintenance

- Bonna pipe is made with cement type V sulfate resistant for seawater application

- Bonna pipe concrete inner wall does not require any specific protection against abrasion thanks to its high strength & compactness

- Concrete high thermal inertia makes the pipeline less sensitive to the weather conditions

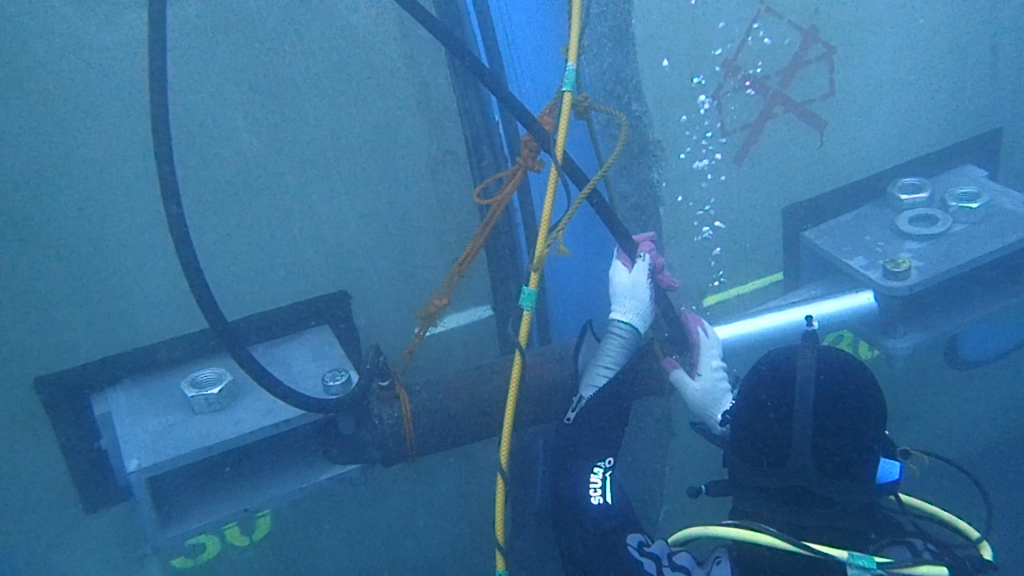

3. Simplified Construction

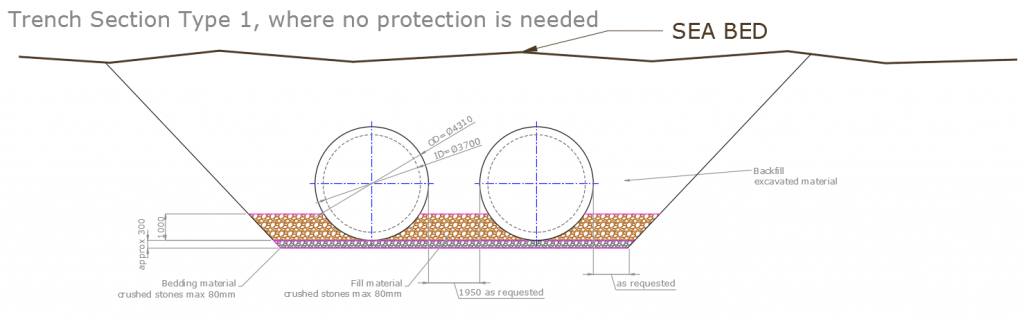

- Onshore welded joint works for segment of 2 or 3 Bonna pipes RCCP

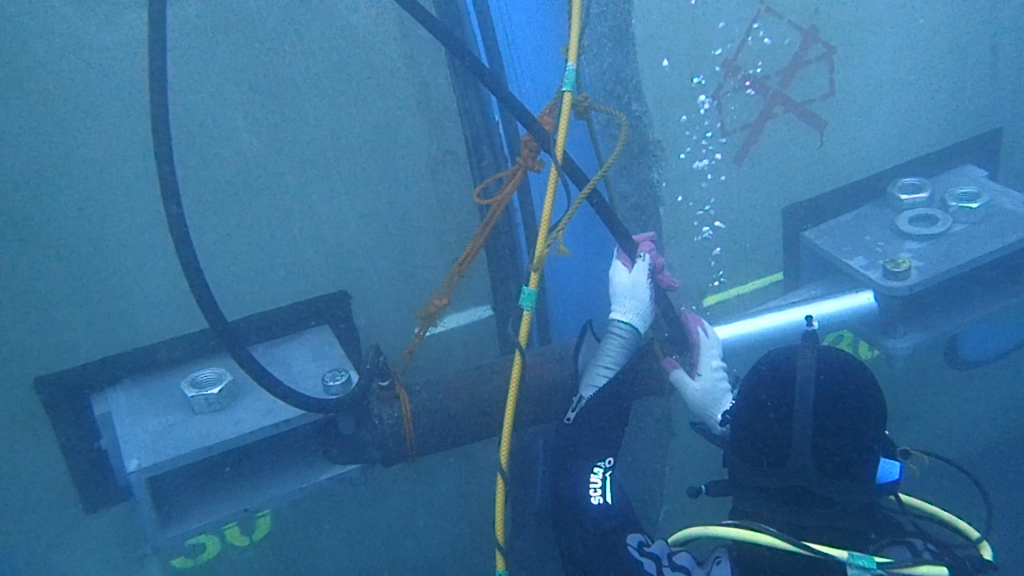

- RCCP segment connections underwater with flexible joints by mean of hydraulic jacks

- No underwater welding works and less civil works (crushed and armor stones & dredged soil disposal)

- Comprehensive design review and preliminary plan & sectional drawing integrate technical discussion to comply with conditions at construction site

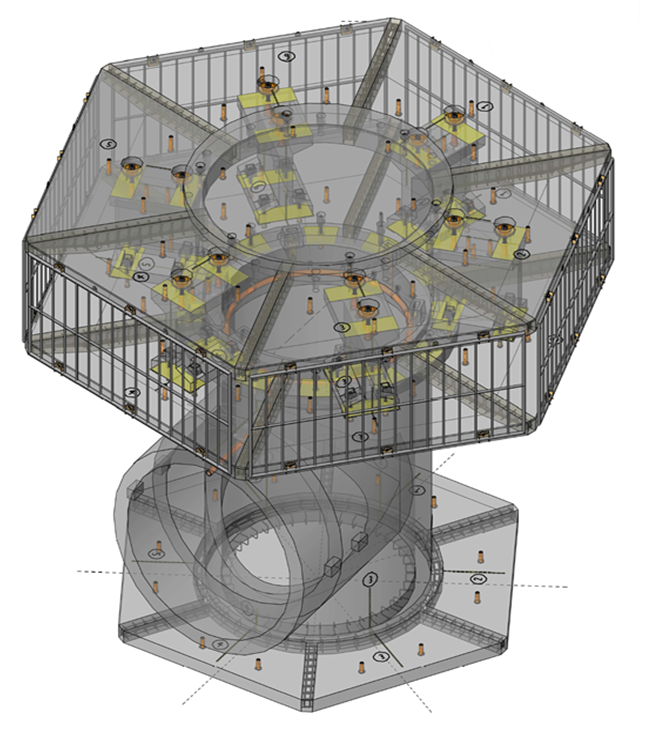

- Bonna Intake Head Delivered on several parts

- Simply assembled on site

- Stabilized by armor stones

4. Low Head Loss

- Roughness Coefficient “k”=0.0001m corresponds to the internal lining of the Bonna pipelines RCCP

- The manufacturing and installation processes for Bonna Pipe RCCP result in pipelines with smooth surfaces across the joints between adjoining pipe units

- The concrete or mortar lining does not deteriorate with age when flowing full

5. Total Custom-made Solution

Before execution of the contract, Bonna Pressure Pipes’ design and engineering office helps customers to optimize their system and works with you for all the technical aspects.

During the performance of the contract, the design and engineering office works out all the technical documents required for the project. In particular:

- The bills of materials and piping arrangement drawings for the pipes and special fittings for manufacturing and for laying

- Detailed drawings of the equipment and/or accessories supplied

- Calculations notes

- The erection manual and instructions on the protection systems to apply on site

Looking for solutions for your next project?

DISCOVER OUR REFERENCES

PLTU Lontar Unit IV

Bonna Indonesia supplies cooling water piping solutions for construction of Unit 4 of Lontar Coal Fired Steam Power Plant in Indonesia.