Inspection & Quality are our top priorities

While our pipes are manufactured to comply with international standards, meeting customer expectations is our top priority. PT. Bonna Indonesia delivers at the end of each project the End of Manufacturing Report (EMR), which encompasses all controls made.

Each project is unique and we are dedicated to provide our customer with high quality and a total solution, thanks to our experience and the Bonna RCCP technology, which is the only one to have the full range of solutions from different pipe diameters to custom-made fittings.

PT. Bonna Indonesia designs the right solution for each project according to the site conditions (soft soils, seismic areas…) and sets high quality standards, while ensuring safety of operation and project planning delivery.

All of our products are subjected to detailed inspection plans...

- Examining the manufacturing request

- Taking delivery of the raw materials and fittings in compliance with the standards

- Inspecting the dimensions of the end joints

- Inspection of dimensions and of watertightness of the steel cylinders

- Inspection of the reinforcements

- Quality of the concrete

- Concrete casting

- Inspection & tests of finished products

- Qualification of staff and of methods

- Control of inspection, measurement, and testing instruments

… with adaptation to local environment and client's requests.

- Operation and Control is performed 24/7 as per internal quality procedures

- Aggregates are conforming with ASTM C33

- Welders are certified

- 3rd party can be delegated

Quality control milestones met during RCCP production

QC 1: Rolling & Bending steel plate

Taking delivery of the steel plate in compliance with the standards.

Control and measurement of the steel plates.

QC 2: Welding, Assembly of rings

Measuring dimensions of the steel cylinder.

Measuring dimensions of end rings.

QC 3: Full welding & Capillary test

Capillary test to control the watertightness.

Control of welding.

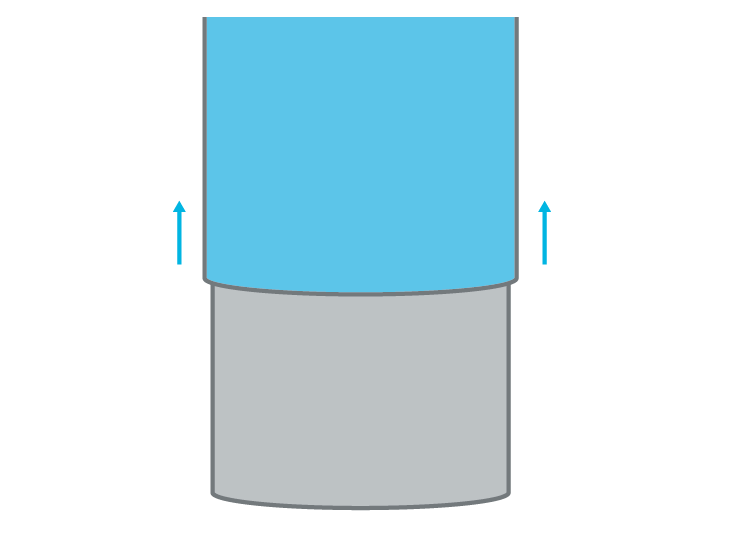

QC 4: Hydrotest for every steel cylinders

Control of steel cylinder watertightness.

Control of mechanical characteristics.

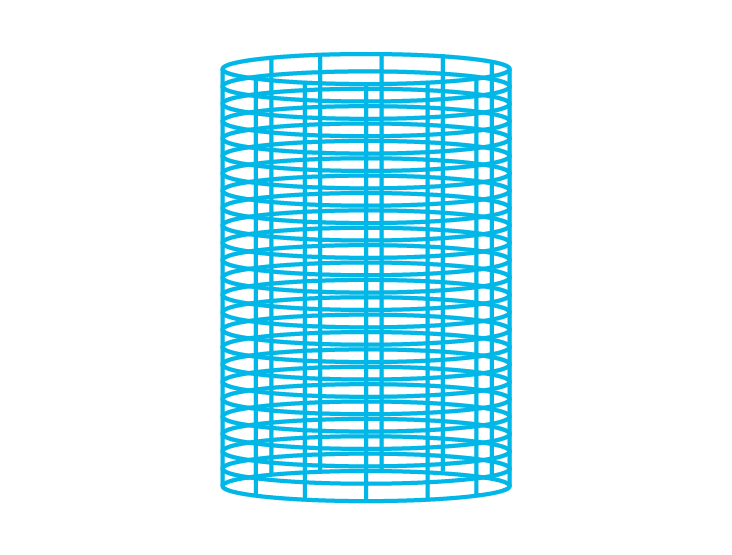

QC 5: Steel bar reinforcement

Taking delivery of the reinforcement wires in compliance with the standards.

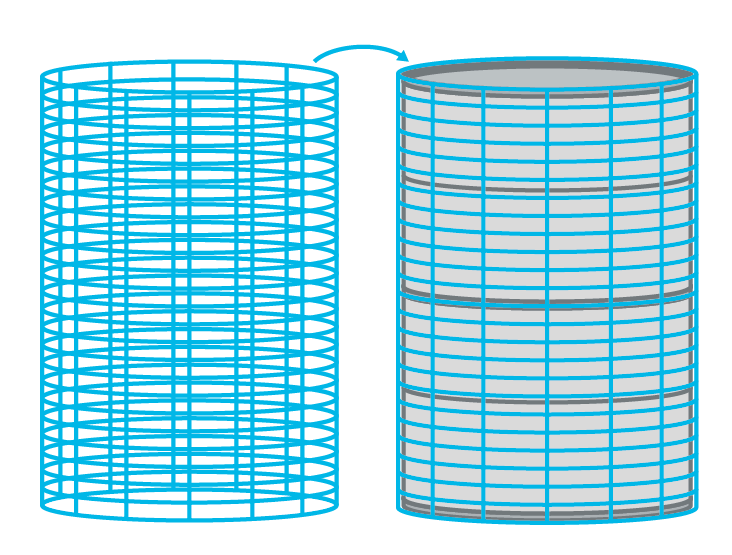

QC 6: Fitting the cage over steel cylinder

Measuring dimensions of the steel cylinder.

Measuring dimensions of the end rings.

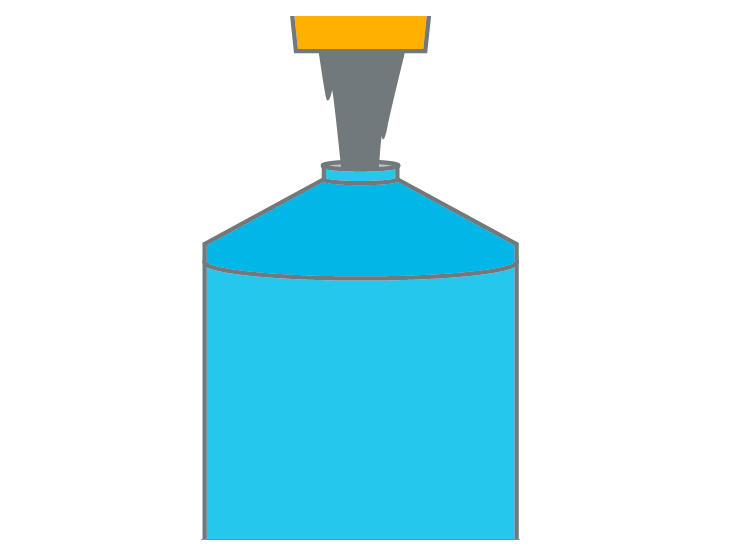

Full QC 7: Vertical casting

Taking delivery of sand, gravel, cement and water in compliance with the standards.

Control of concrete strength.

QC 8: Unmoulding

Control of concrete casting.

Control of concrete quality.

QC 9: Curing

Control of concrete quality.

QC 10: Finishing and QC Inspection

Control and test of finished products.

Final dimension measurements.

QC 11: Delivery on-site

Inspection of trucks.

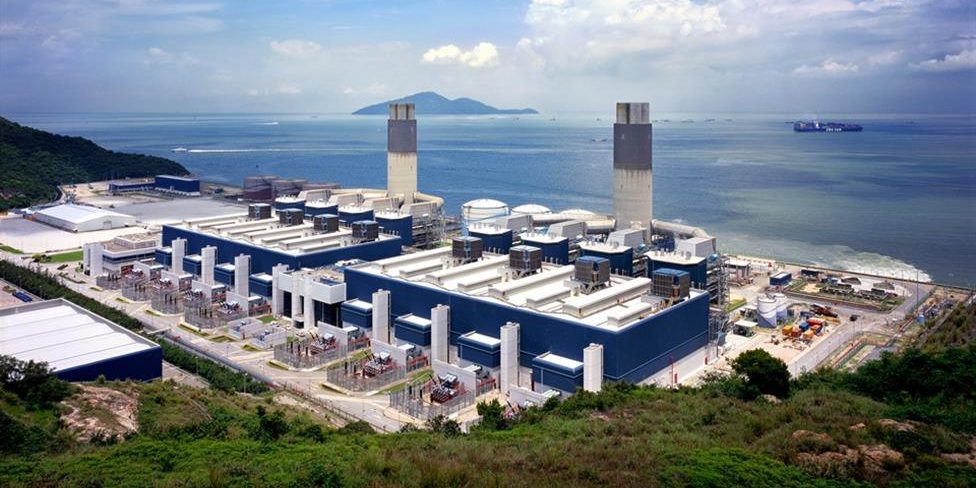

DISCOVER ONE OF OUR REFERENCES:

Black Point Combined Cycle Power Plant

Bonna Indonesia delivers solutions to the extension of Black Point Power Plant in Hong Kong. Located in the New Territories region of Hong Kong, Black Point is one of the world’s largest gas-fired combined-cycle power stations. Bonna Indonesia supplied RCCP pipes & special fittings for the onshore & jacking of the cooling watersystem.